Three-dimensional Bioprinter

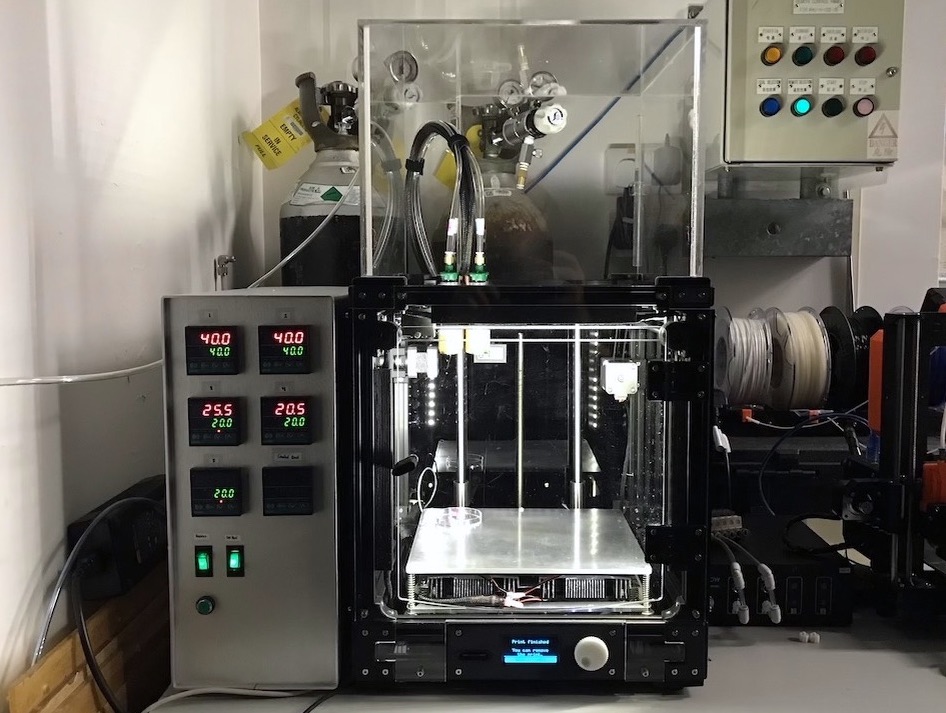

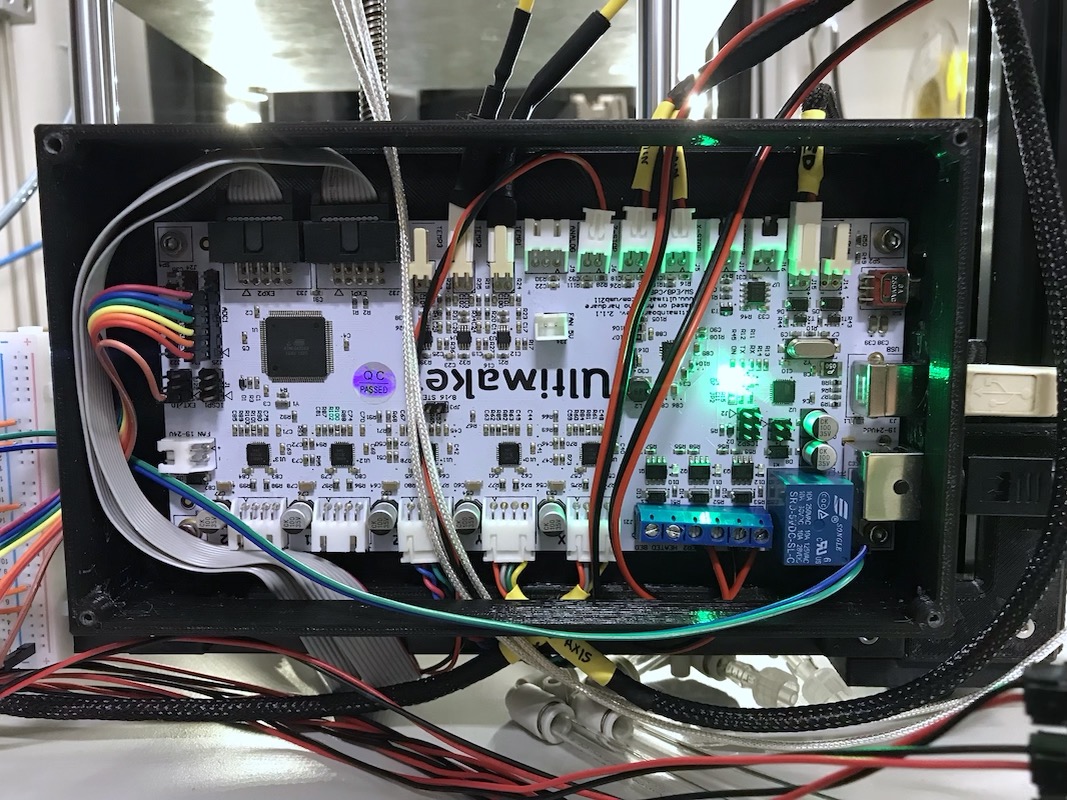

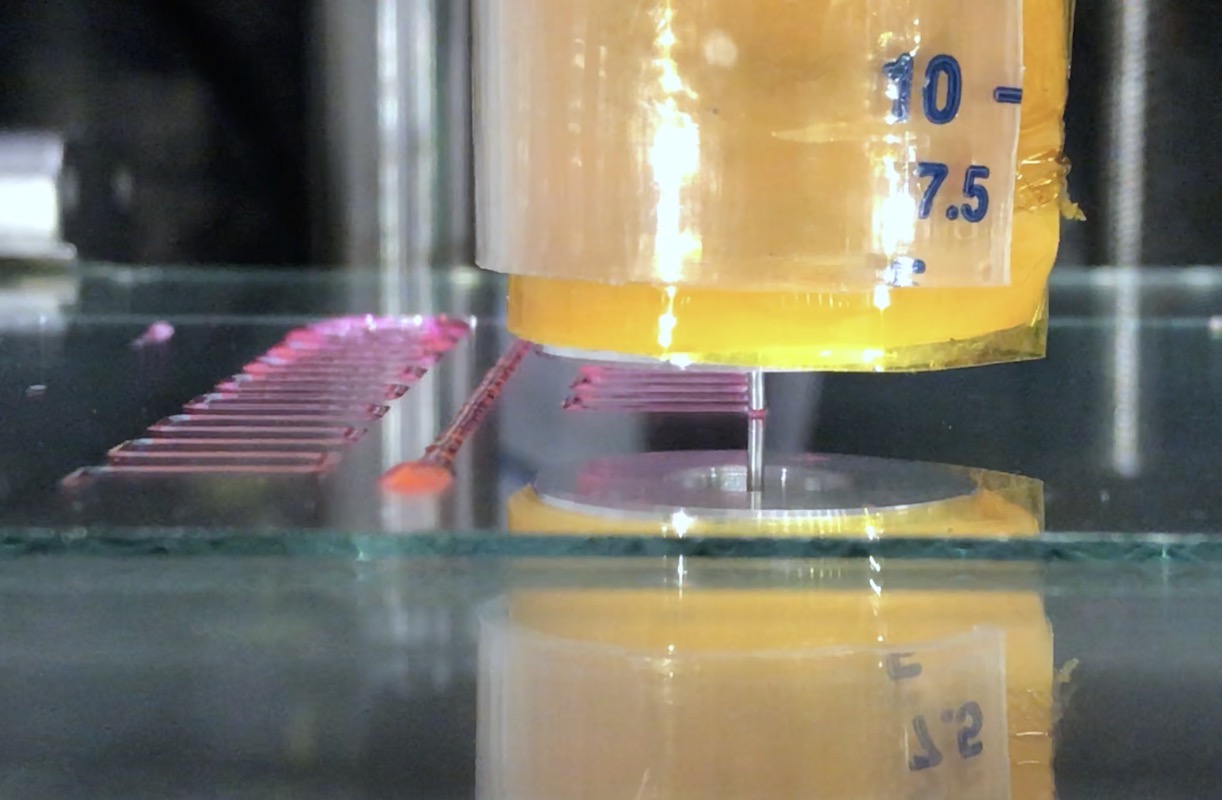

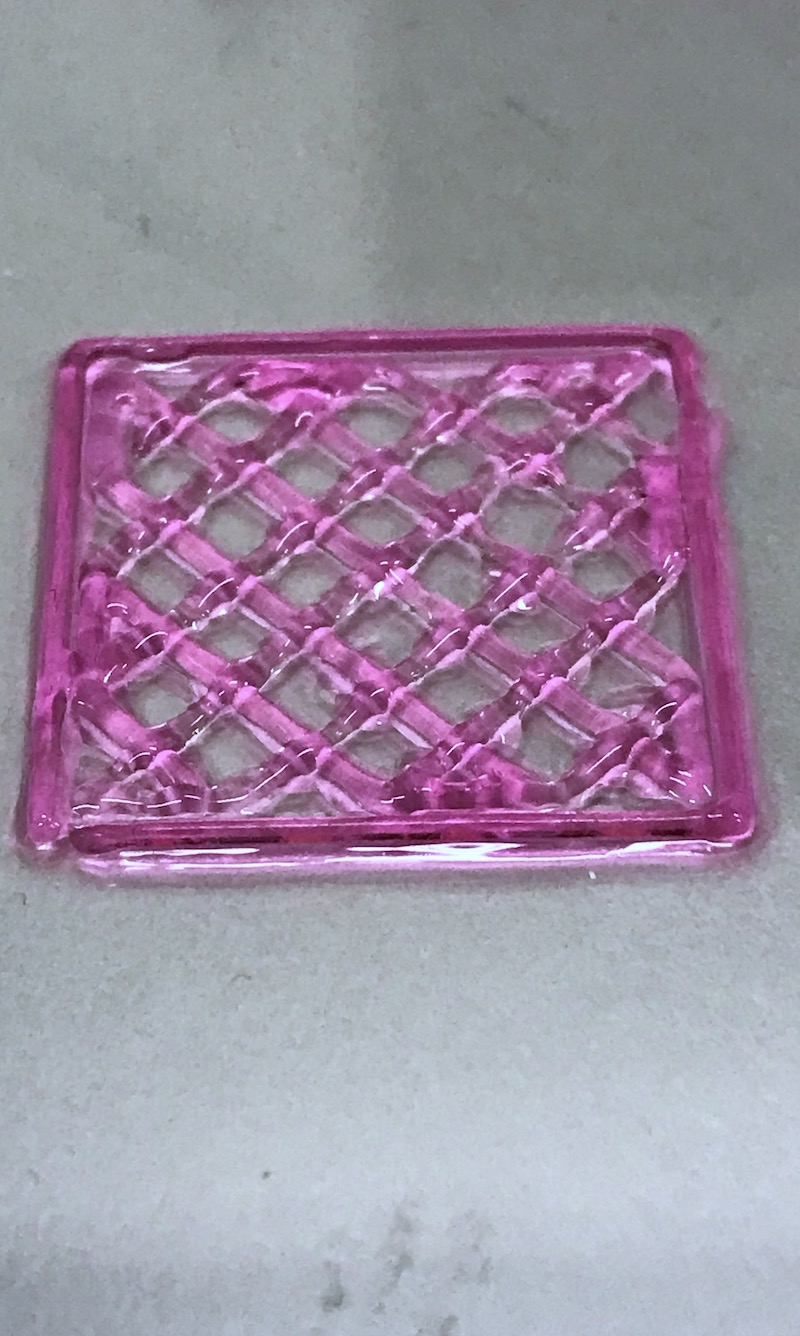

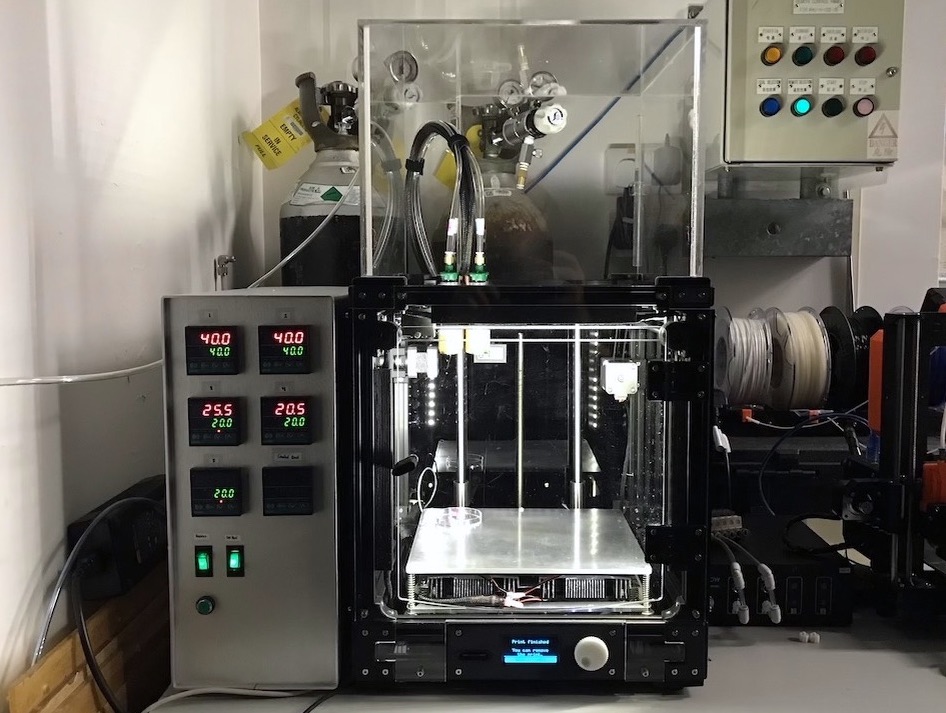

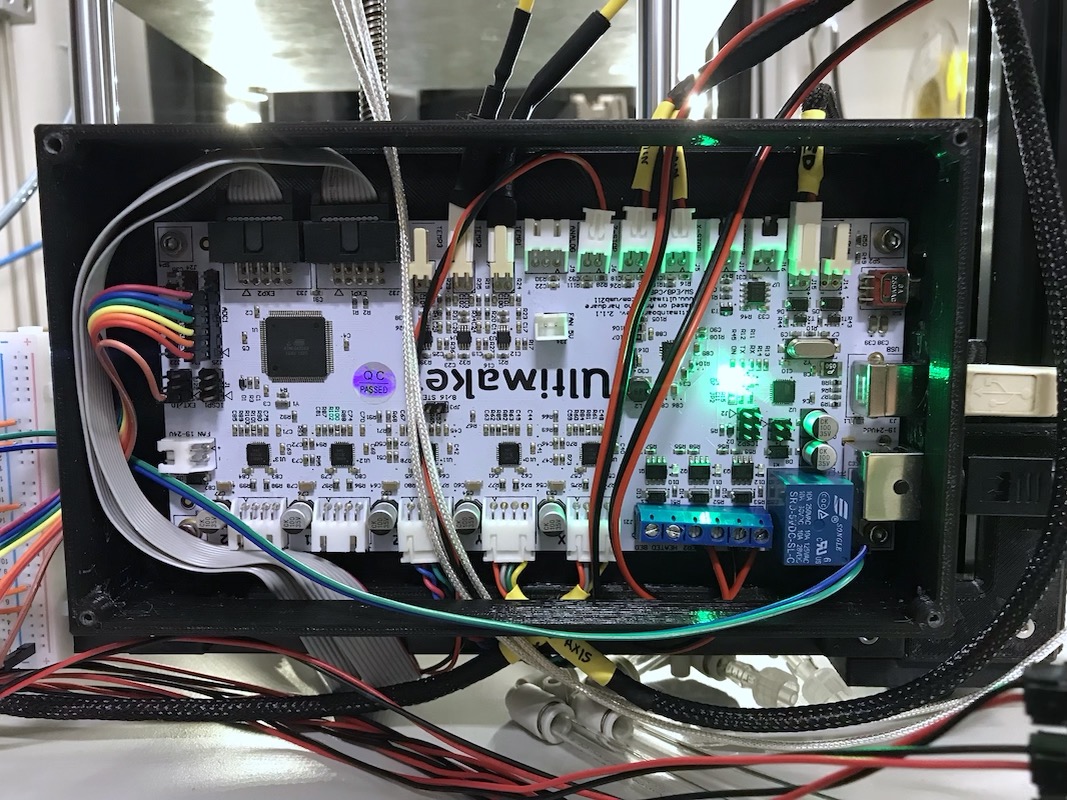

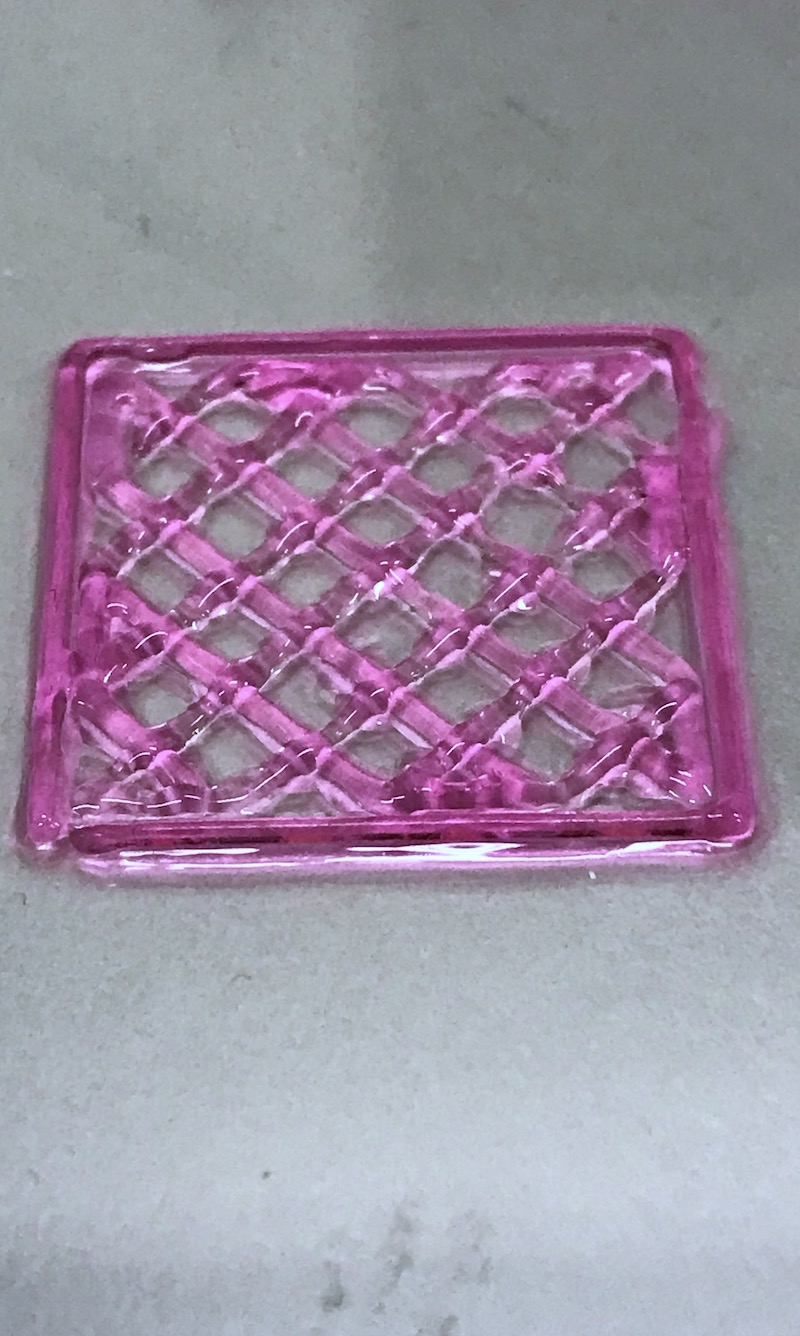

We built a low-cost 3D bioprinter for tissue engineering applications. The printer is based on the Ultimaker 2 design and was built with an aluminum extrusions frame. A bioprinter controller was designed to externally control the heated syringe temperature, cooled bed temperature and pneumatic pressure for the syringe extruders.

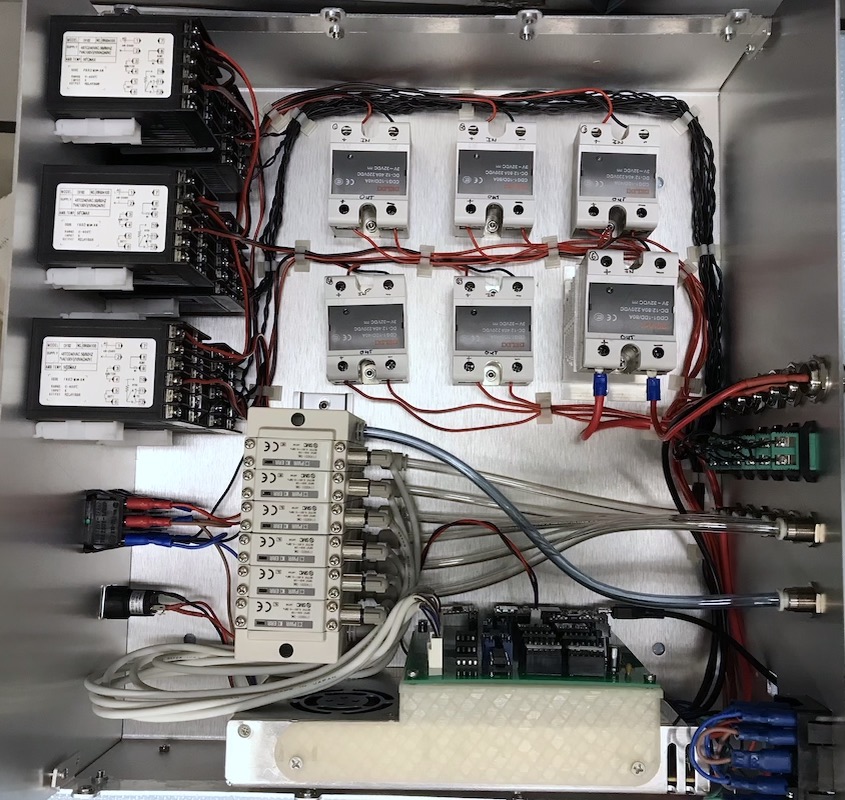

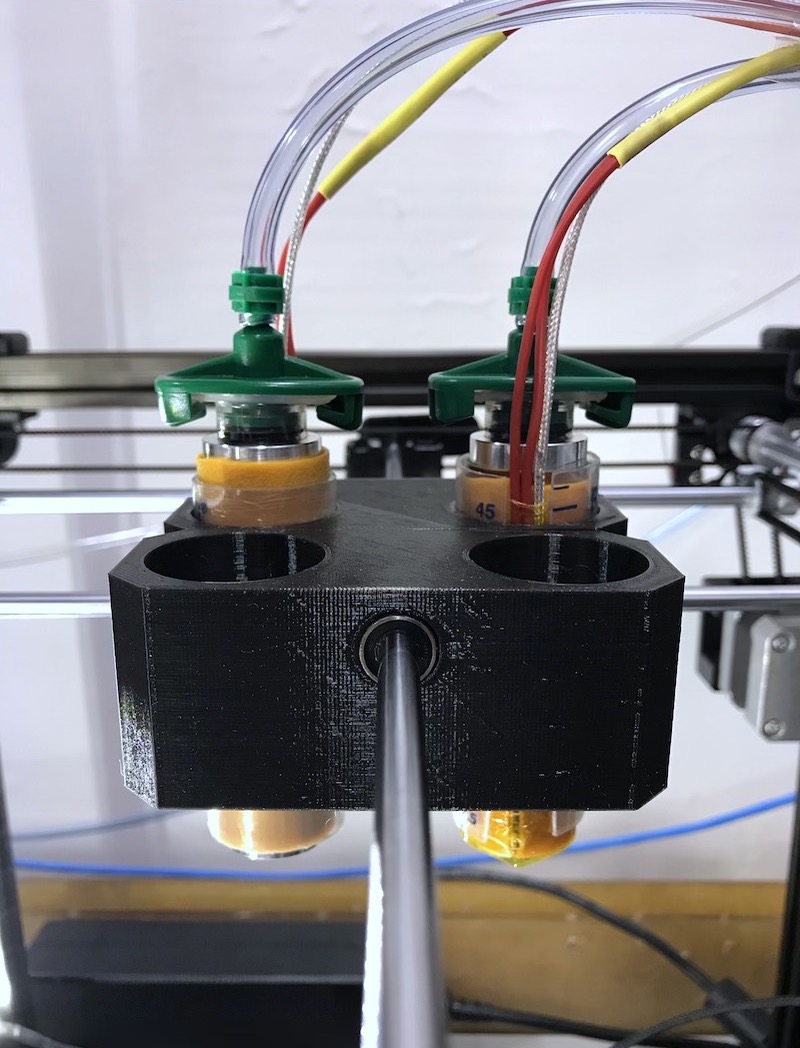

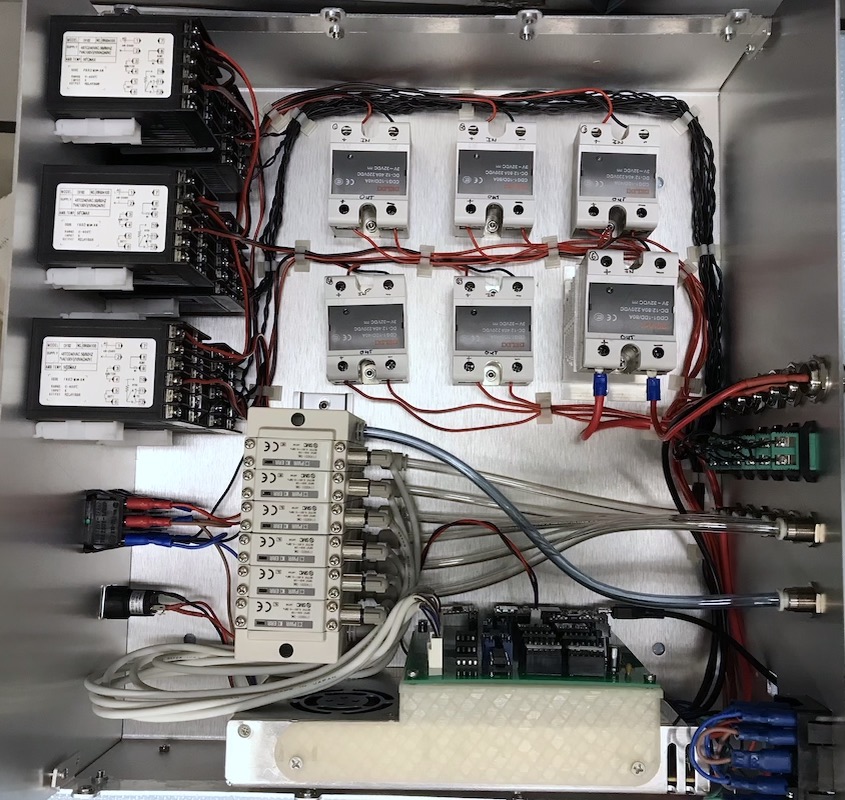

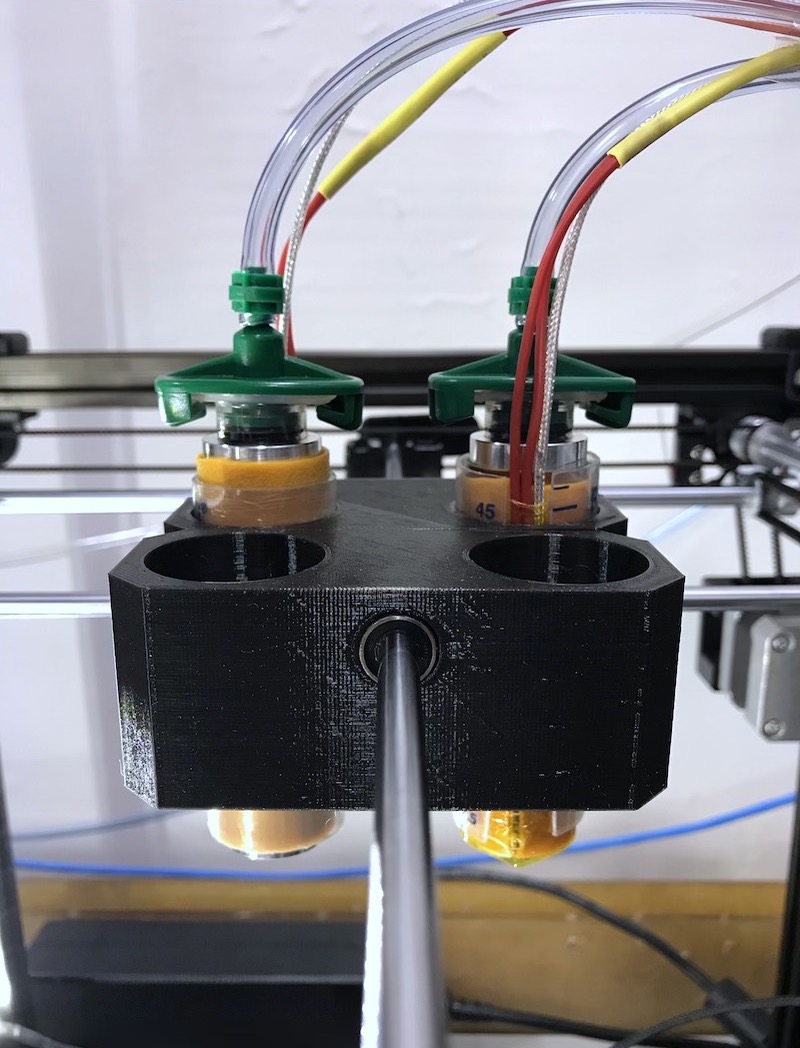

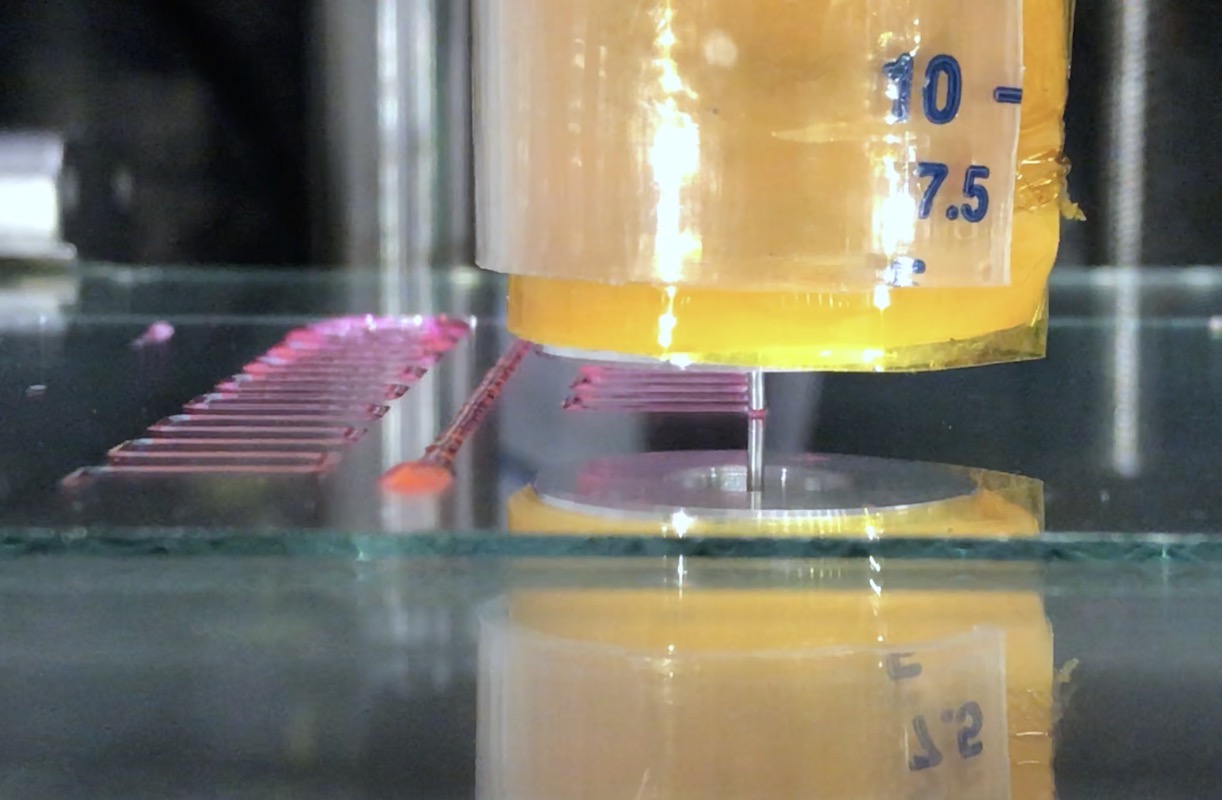

The bioprinter has a modular printhead assembly, allowing additional printheads to be added or removed depending on the desired number of materials or print area. The print heads are inserted into an aluminum heater block, allowing easy insertion and removal, height adustment as well as uniform and stable temperature. A peltier based cooled bed ensures that rapid gelation of physically cross-linked hydrogels. Extrusion was controlled by turing solenoids on/off via g-code commands to the electronic controller board and a solid state relay switching board (schematics). A custom slicer was developed to automate the generation of g-code for pneumatic based printing techniques.

Additional information and files will be published shortly.